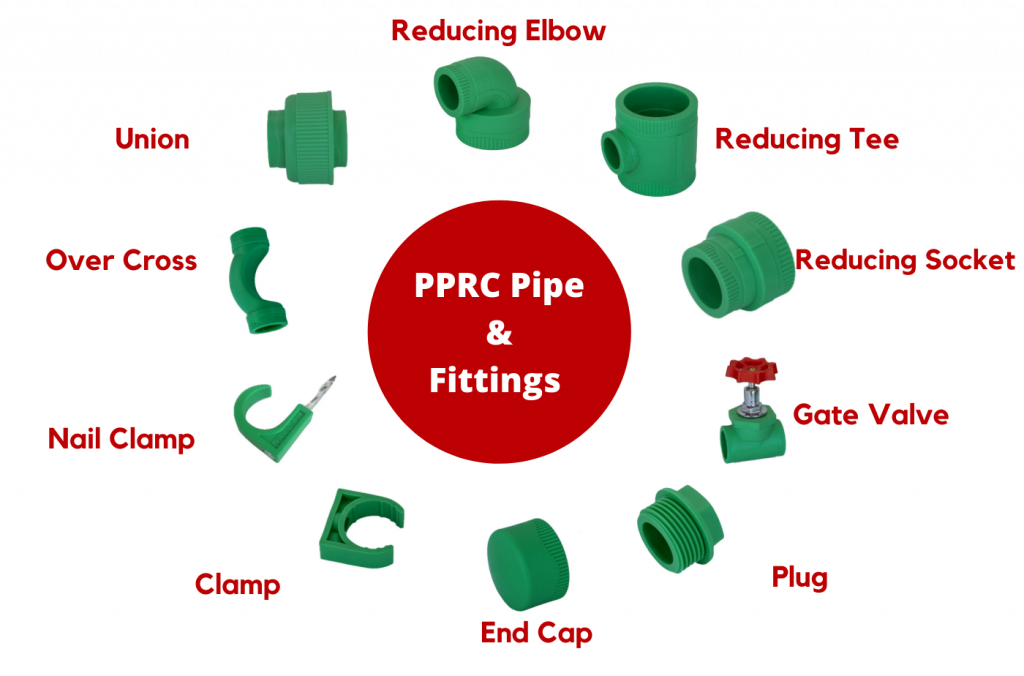

Random polypropylene copolymer pipes, often known as PPRC or PP-R (random polypropylene) pipes, have several applications.

It is a material with a high capability for meeting the design requirements of each scenario. Different diameters, thicknesses, and strengths, as well as the insertion of auxiliary components, complementary parts, or the adaptability of ends to any bonding system, are qualities that make PPRC a product that should always be included in the design and construction of pipes.

The use of Dura Max PPRC Pipes has helped to finally overcome the previous concerns with mechanical behavior, wateriness, and durability.

Poor assembly, however, may derail any attempt, even if it is done with the best materials available. Here are a few examples:

Anti Microbial Protection:

Moreover, Polypropylene copolymer pipes used for drinking water distribution shall not contaminate or deteriorate the quality of water delivered with germs or chemicals that might endanger consumer health. The increased concern about water quality in distribution systems has resulted in a system enhancement by integrating a unique antimicrobial additive that successfully inhibits the growth of bacteria and fungus inside pipe walls.

Anti-dilation Pipeline systems

The Systems are made of plastic materials and have a high degree of expansion owing to variations in fluid temperature. Also, adding microfibers decreases the dilation coefficient by 75%, resulting in a dilation coefficient of 0.04 mm/moC. The meshing of microfibers and the addition of a compatibility additive increase the mechanical strength of the system.

Anti-incrustation protection:

The roughness of the pipes and the fluid quality are factors that favor the inlays. Increased scales result in a smaller section, more load loss, and higher energy consumption. Moreover, Dura Max PPRC pipes are entirely smooth, with no section decreases over time, ensuring the invariability of their roughness coefficient.

Physical Deterioration Resistance

Abrasion is a natural occurrence in all types of pipes. To eliminate deposits, any sanitation system necessitates cleaning operations using high-pressure water. Dura Max PPRC pipes are less prone to abrasion and are not harmed by cleaning operations.

Safety

A sanitary system must be watertight. Dura PPRC pipes are built with elastic joints that assure sealing.

Economical:

Dura PPRC pipe is unrelated to the petrochemical sector; its cost is cheaper and constant.

Ecological

Since its inception, the copolymer tube has been a product that preserves the environment. It is biodegradable and does not release harmful waste during manufacturing or operation. Installation in the open without protection. Contact Dura Max PPRC Pipe and Fittings for more details.