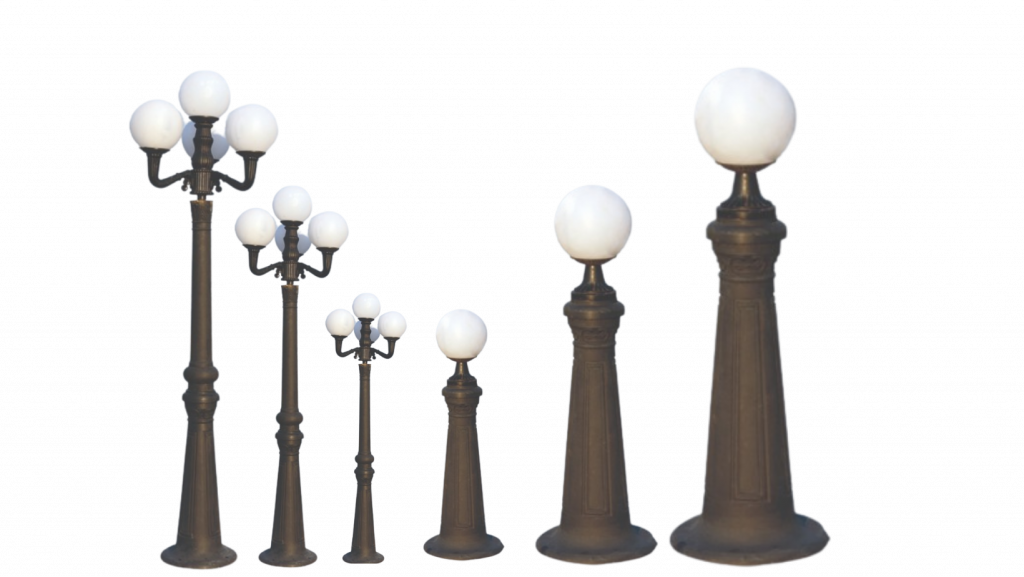

The Importance of Dura Light/Lamp Poles and How to Keep them from residential streets and housing projects to parking lots, restaurants, retail malls, and industrial facilities, light/lamp poles play a crucial part in the safety and security of everything. Because of the impacts of wind, vibration, and corrosion in a typical outdoor setting, periodic inspections and maintenance are required to guarantee that a light pole is safe and structurally sound.

Maintenance of Light/Lamp Poles:

Winds, vibration, metal fatigue, and corrosion may erode a light pole’s structural integrity over time, increasing the likelihood of it could tumble during bad weather or an accidental hit. Routine inspections and maintenance are crucial to avoiding injuries, property damage, and operational failures. Typically, this includes:

- Inspecting the light pole base:

The base of a light pole is the most crucial portion. Welds between the base plate and the bar might fail due to wind and vibration. Welds should be checked for cracks, flaking, and other damage and fixed as needed.

- Examining the pole for corrosion damage:

The entire pole should be inspected for rust and corrosion, weakening the metal and making it prone to fractures or breaks. If corruption is discovered, it may be measured using a hammer and punch, with any denting, flaking, or deformation indicating substantial damage. If accessible, ultrasonic equipment can be utilized for a more complete check.

- Fastener inspection:

Bolts, nuts, and screws can become loose over time. To avoid tampering, each fastener should be checked for tightness, and nut covers, if fitted, should be changed. Any issues should be resolved.

- Inspecting Hand Hole and Base Covers:

Handhole and base covers should be examined and replaced if missing or damaged.

- Electrical system:

The light pole should be examined for stray currents, poor grounds, shorts, and other electrical faults to minimize shock dangers and accidents.

- Replacing bulbs:

Check bulbs and ballasts for good operation and replace any burned-out or damaged ones.

- Control system testing:

Moreover, Photosensors, timers, and other controllers should be examined for correct operation and, if required, fixed or replaced.

Contact Dura Max Poly Lights Division for more details.