Plumbing is the unsung hero of any residential, commercial, or industrial building—quietly ensuring that clean water flows in and waste flows out. With growing demands for safe, efficient, and durable plumbing systems, PPRC (Polypropylene Random Copolymer) pipes and fittings have become the modern benchmark for high-performance water delivery systems.

PPRC pipes are trusted worldwide for their reliability, longevity, and resistance to extreme temperatures and corrosion. In this blog, we’ll explore their features, benefits, applications, and how they compare with other piping systems commonly used today.

What Are PPRC Pipes and Fittings?

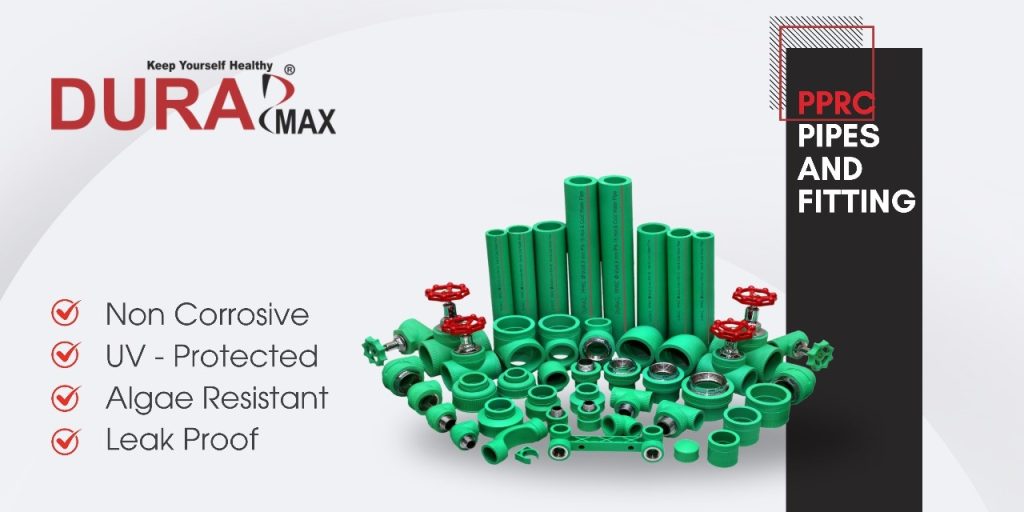

Dura PPRC is a type of plastic polymer developed specifically for pressure piping systems. The pipes and fittings are made from polypropylene random copolymer, a material known for its superior toughness, thermal resistance, and chemical inertness.

Unlike PVC or metal pipes, Dura PPRC systems are joined through heat fusion, which bonds the pipe and fitting into a single leak-proof unit. This makes them ideal for high-pressure and high-temperature applications like hot water delivery and chemical transport.

PPRC Fittings Key Features and Benefits

1. Heat Resistance

Dura PPRC pipes can withstand temperatures up to 95°C, making them ideal for hot water systems in homes, hotels, hospitals, and factories.

2. Corrosion and Scale Resistance

These pipes are completely resistant to chemical reactions, corrosion, and mineral scaling. This preserves water purity and system efficiency over time.

3. Long Life Span

Under normal conditions, Dura PPRC piping systems can last 50 years or more, with minimal maintenance required.

4. Non-Toxic and Hygienic

Being made of food-grade material, Dura PPRC is safe for drinking water applications and does not leach harmful chemicals into the water.

5. Leak-Proof Joints

Heat fusion welding ensures a permanent connection—no glue, no threading, no leaks.

6. Energy Efficient

The low thermal conductivity of Dura PPRC reduces energy loss in hot water systems, saving on heating costs.

Applications Across Sectors

- Residential Homes: For both hot and cold water piping.

- High-Rise Buildings: Withstand pressure variations over multiple floors.

- Hospitals and Laboratories: For sterile water distribution.

- Factories and Industrial Plants: For transporting chemicals and process water.

- Agricultural Use: For irrigation and livestock water systems.

Comparison: PPRC vs. Other Pipe Types

Below is a detailed comparison of PPRC, PVC, CPVC, and metal (GI/steel) pipes:

| Feature | PPRC | PVC | CPVC | Solvent cement (can degrade. |

| Material | Polypropylene Random Copolymer | Polyvinyl Chloride | Chlorinated Polyvinyl Chloride | Galvanized Iron/Steel |

| Temperature Tolerance | Up to 95°C | Up to 60°C | Up to 90°C | Up to 70°C (rust issues) |

| Corrosion Resistance | Excellent | Good | Good | Poor (prone to rust) |

| Life Expectancy | 50+ years | 20–25 years | 30–40 years | 10–20 years |

| Joint Type | Heat fusion (leak-proof) | Solvent cement can degrade. | Solvent cement | Threaded/Welded (may leak) |

| Water Quality Impact | Neutral, hygienic | May degrade over time | Safe for potable use | May rust and contaminate water |

| Cost (Initial) | Moderate | Low | Moderate-High | High |

| Installation | Easy, clean, fast | Easy but chemical-laden | Requires care | Labor-intensive, heavy |

| Environmental Impact | Recyclable, non-toxic | Non-biodegradable | Non-biodegradable | Recyclable but energy-intensive |

Summary:

- PPRC vs PVC: PPRC wins in heat resistance, longevity, and joint reliability.

- PPRC vs CPVC: CPVC is similar but more brittle and costly; PPRC is easier to install and longer-lasting.

- PPRC vs GI/Steel: PPRC is lighter, non-corrosive, and much easier to install.

Environmental Benefits of PPRC

With sustainability becoming a growing concern, Dura PPRC scores well. It is 100% recyclable, free from harmful chemicals like BPA, and has a much smaller carbon footprint compared to metal production. Its longevity also means fewer replacements and less material waste over time.

Moreover, its insulation properties reduce energy waste in hot water systems, aligning with green building practices and certifications like LEED.

Maintenance and Safety Tips

To get the most out of a Dura PPRC system:

- Always use proper tools for heat fusion to ensure perfect jointing.

- Avoid exposure to UV rays for extended periods; consider covering exposed external pipelines.

- Use appropriate pipe thickness according to pressure and temperature requirements.

PPRC pipes rarely require maintenance, but it’s good practice to check joints and valves annually in high-demand systems.

The Future of PPRC in Infrastructure

As urbanization accelerates and infrastructure standards rise, demand for reliable, hygienic, and cost-effective plumbing materials is growing. Dura Max PPRC fits perfectly into this vision, offering versatility for new installations, reliability for high-pressure needs, and durability for the long haul.

Smart home builders, real estate developers, and engineers are increasingly choosing PPRC over traditional materials due to its superior performance across a wide range of conditions.

Whether you’re a homeowner, contractor, or infrastructure planner, Dura Max PPRC pipes and fittings offer an unmatched combination of strength, hygiene, efficiency, and cost-effectiveness. With rising standards for water safety and sustainability, investing in a PPRC piping system is a forward-thinking decision.

Not just a pipe, it’s peace of mind—built to last for generations.