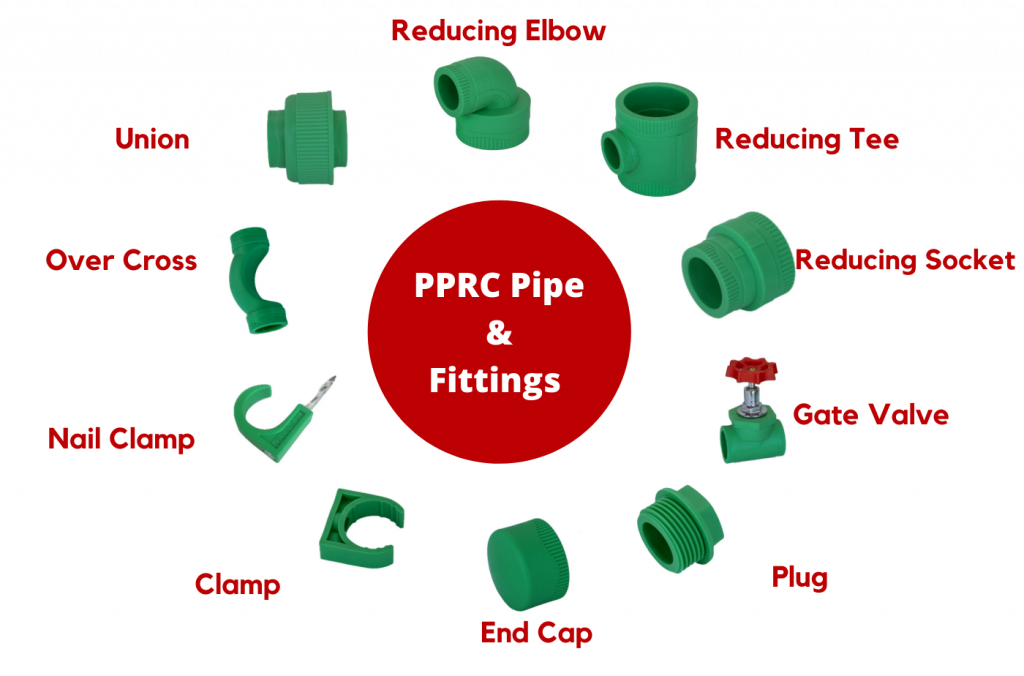

Dura Max offers excellent PPRC Fittings products such as Gate Valve. Gate valves are used in the opening and shutting of pipes. Which are gradual; they cannot produce a water hammer. As a result, some organizations demand that the valve closest to the water meter be a gate valve. Gate valves are highly durable and perform admirably in settings where corrosion is a significant concern. Because this material can withstand high temperatures, it is often employed in manufacturing applications.

Gate valves are often used to control the flow of liquids in larger sections of pipes. They are specifically intended to prevent the start and stop of liquid flows. There are several types of gate valves. They can have rising or non-rising stems, solid wedges, flexible wedges, or split wedges. Here are the three most significant advantages of installing gate valves.

1. Full Open/Close Capabilities: Gate valves can be opened and closed completely. This permits goods to be conveyed to flow in a straight line with nothing impeding their progress. This is especially useful when working with bulkier materials that require unhindered flow.

2. Ease of Operate: The gate valve is effortless because it does not contain complicated mechanisms. The spindle wheel revolves to raise and lower the gate, allowing the valve to open and close the gate between its circular openings.

3. Damage Control: Gate valves are handy for halting the flow of liquids when partial discharge would otherwise cause irreversible damage to pipelines and systems. When the valve fully opens, the gate is not exposed to the flow of materials, preventing harm from strong material currents. This prevents the gate from bending or closing off-center due to the tremendous stresses of everyday material flow transit.