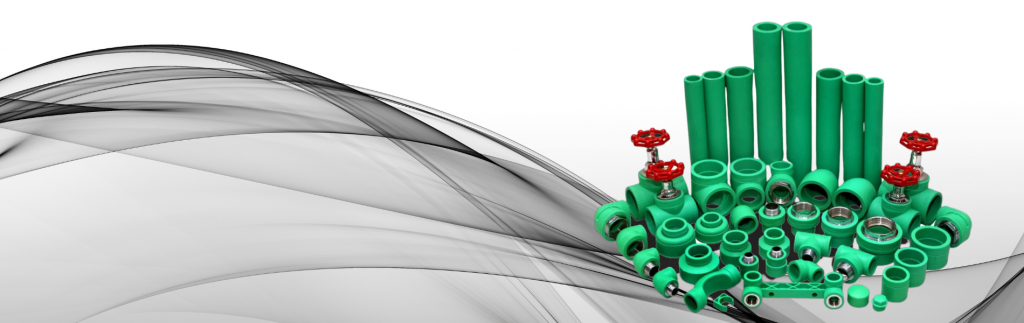

When it comes to plumbing systems, PPRc (polypropylene random copolymer) pipes have become a preferred choice for both residential and commercial applications. Known for their durability, corrosion resistance, and long lifespan, PPRc pipes are ideal for transporting hot and cold water. However, the efficiency and reliability of a PPRc piping system largely depend on the fittings used.

So, what fittings are used in PPRc pipes?

PPRc pipes require specific fittings to create a functional and leak-proof piping system. These fittings come in various shapes and sizes, each serving a unique purpose. Let’s take a closer look at some of the

Common types of PPRc fittings:

1. Elbows

Elbows are used to change the direction of a pipe. The most commonly used elbow fitting is the 90-degree elbow, which redirects the pipe path at a right angle. Elbows are essential when the layout of the plumbing system requires turns around corners or other obstacles.

2. Couplings

Couplings are simple yet vital fittings used to connect two PPRc pipes of the same diameter. They ensure a secure and straight pipeline extension, especially in long stretches of piping. Couplings are available in both equal and reducing types, depending on whether the connected pipes are of the same or different sizes.

3. Tees

Tee fittings allow a single pipe to split into two or more branches. A standard tee has one inlet and two outlets, arranged at a 90-degree angle to the main pipe. This makes it ideal for branching out water supply lines to different areas. There are also reducing tees, which connect pipes of different diameters.

4. Crosses

A cross fitting connects four pipe sections—two on the horizontal axis and two on the vertical. Though less common than tees, crosses are useful in complex piping networks where multiple lines intersect.

5. Reducers

Reducers are used to connect pipes of different diameters, allowing the flow of water from a larger pipe to a smaller one or vice versa. They help maintain pressure and manage flow rates in the system.

6. Adapters

Adapters are crucial when joining PPR pipes to other materials, such as metal or PVC. They come with threaded ends and enable transition between different piping systems, making them extremely versatile in mixed installations.

Advantages of PPRc Pipes & Fittings

- Corrosion Resistance

PPR pipes are highly resistant to rust, scale, and chemical corrosion, making them ideal for long-term water supply systems. - High Temperature Tolerance

They can withstand high temperatures, making them suitable for both hot and cold water applications. - Long Lifespan

PPR pipes have a service life of up to 50 years under normal operating conditions. - Smooth Inner Surface

The smooth interior minimizes pressure loss and prevents scaling or deposit buildup. - Non-Toxic and Safe

Made from food-grade materials, PPR pipes are safe for drinking water systems. - Leak-Proof Joints

Heat fusion welding creates strong, seamless joints that prevent leakage. - Low Thermal Conductivity

Helps in maintaining water temperature, reducing heat loss in hot water systems. - Lightweight and Easy to Install

PPR pipes are lightweight, making transportation and installation easier and more cost-effective. - Eco-Friendly

They are recyclable and do not release harmful chemicals during installation or use.

A well-installed PPRc system, complete with the proper fittings—such as elbows, couplings, tees, crosses, reducers, and adapters—can provide long-lasting and reliable service. However, it’s important to understand its limitations. If you’re working in an environment where hot, chlorinated water is present, consider whether PPRc is the right choice. By knowing both the strengths and weaknesses of PPRc piping, you can design more resilient and efficient plumbing systems.