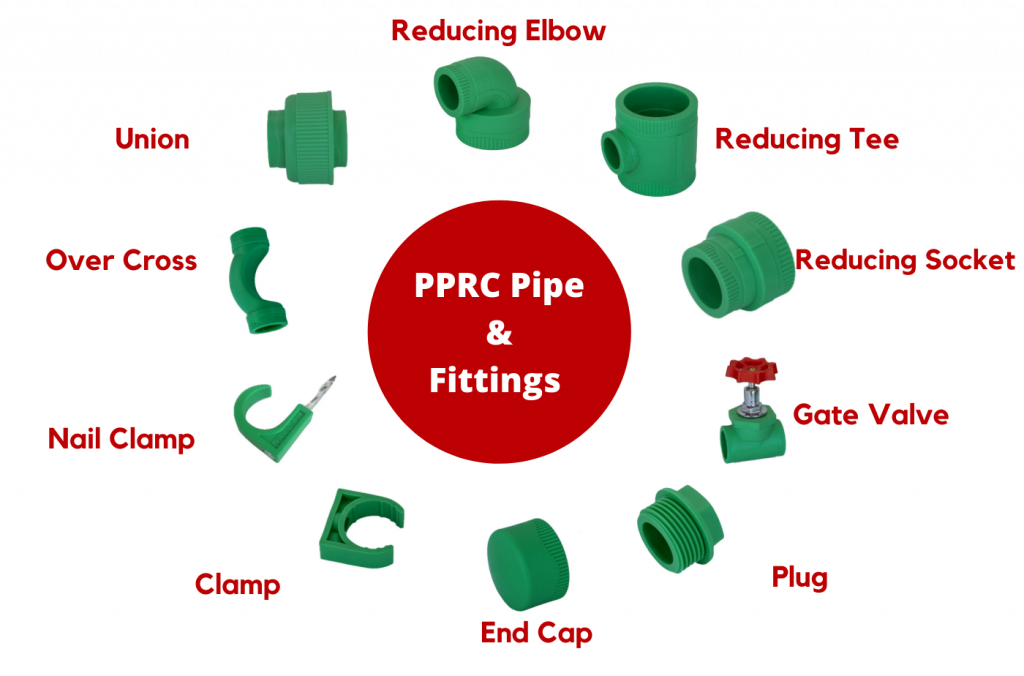

PPRC pipe, also known as Polypropylene Random Copolymer pipe, is a cylindrical and rigid PPRC pipe. The pipe is manufactured in a continuous process called extrusion. Dura Max PPRC pipe is often green in color. Most PPRC pipes range in diameter from 20mm to 110mm. This indicates that Dura Max PPRC pipes are thicker than PVC pipes. PPRC pipes also include a network of fittings, accessories, and components. These attachments are available in various sizes to fit each PPRC pipe diameter.

Most Common Applications for Dura Max PPRC Pipe?

As previously stated, PPRC pipes have various economic, environmental, and durability advantages. This is why these pipes are employed in so many different applications. Continue reading to learn about the principal applications of PPRC pipe fittings:

Dura Max PPRC pipe & fittings are commonly utilized in the design of cold and hot water systems. PPRC pipes are the finest choice for cold and hot water systems due to their ability to handle hot and cold temperatures without breaking or cracking. Furthermore, its low thermal conductivity ensures that the fluids maintain the necessary temperature.

PPRC fittings are the preferred method of releasing chemical fluids, including industrial waste. Because of its capacity to handle solid chemicals and alkaline solutions, PPRC piping is the ideal pipe fitting for industries.

Purified water delivery systems also employ PPRC pipe fittings. These pipes are long-lasting, with a lifespan of more than 50 years. Furthermore, even under extreme conditions, they do not easily shatter or crack.

PPRC pipes are ideal for use in a building’s heating system. These pipes can be put in flooring, radiant heating, and wall heating systems. These pipes can endure all surfaces and situations, making them an excellent choice for your heating requirements.

For Orders or details or check the PPRC fittings Page, kindly contact our UAN: 042 371 33 111 or contact us through our Social Media Pages.