In this modern age, where electrical infrastructure happens to be one of the fastest-evolving fields of human endeavor, the need for robust and reliable materials cannot be overstated. In this context, among various choices of electrical conduits, Dura Conduit Pipes & Fittings happens to be one of the best in the market in terms of reliability and durability. These pipes and fittings provide the electrical systems of industries with protection, durability, and efficiency with high accuracy and quality. Dura Conduit’s products are invaluable for shielding electric wiring in any residential, commercial, or industrial application.

Let’s break down what makes Dura Conduit Pipes & Fittings exceptional, their applications, benefits, and why they are a must in modern construction in this blog.

What are Dura Conduit Pipes and Fittings?

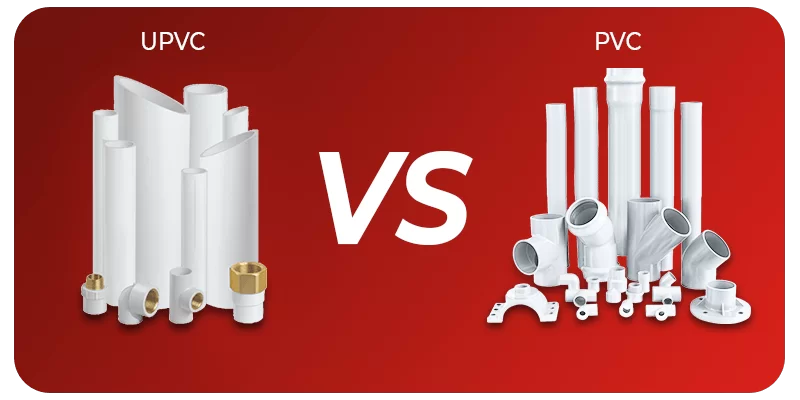

Dura Conduit Pipes are rigid or flexible, tubular structures that have been put in place to encase and protect electrical wiring. They serve as a shield that safeguards cables from external elements including moisture, dust, physical strain, and even chemical contact. The term “conduit” refers to the channel through which electrical cables pass, and the pipes themselves are made of different materials such as PVC (Polyvinyl Chloride), steel, or flexible plastic.

Fittings are referred to as parts that compose the conduit system, which is flexible, functional, and adaptable to a variety of structural arrangements: those parts that make up the connectors, elbows, and junction boxes. These fittings ensure that the conduit system acts cohesively as a whole by giving secure connections and smooth pipe-to-pipe transitions.

Why Choose Dura Conduit Pipes & Fittings?

There are various reasons why Dura Conduit Pipes & Fittings have been so popular in construction and electrical industries:

1. Durability: As the name itself suggests, Dura Conduit products are known for their durability that lasts long. They are designed to endure extreme conditions such as heavy loads, fluctuating temperatures, moisture, and even chemicals. There are many environments where other materials may wear out or degrade, but Dura Conduit Pipes maintain the integrity of their form.

2. Safety: Electrical systems are most sensitive to safety. Dura Conduit Pipes and Fittings ensure the safety of electrical wiring against environmental and physical hazards in the form of fires, electric shock, and so on. They also protect against short circuits due to the insulation of electrical cables from potentially harmful elements.

3. Corrosion Resistance: This is one of the main benefits of Dura Conduit Pipes, especially those made from PVC or Stainless steel types, which have inherent resistance against corrosion. Even in the roughest environments, such as in industrial facilities or places with high humidity, these pipes can last longer, resisting corrosion as opposed to some other metals used in conduits.

4. Ease of Installation and Maintenance: Dura Conduit Pipes & Fittings are designed to be lightweight yet robust for easy transportation to the site location; they can easily be installed on-site. The provision of a good range of accessories can allow these pipes to be changed in configuration to suit site needs, making it easy to work around an obstacle or change of layout.

5. Economically Viable: Besides their life, Dura Conduit products are the most economical in the long term. A lesser need to replace or repair due to their durability and resistance to damage reduces the costs of maintenance. This makes them very popular for large projects when budget and performance are key considerations.

Applications of Dura Conduit Pipes & Fittings

Dura Conduit Pipes & Fittings have some versatile applications across many sectors, among which are:

1. Residential Buildings: In residential buildings, the conduit pipes protect electrical wiring in walls, ceilings, and underground, ensuring that whether it is lighting fixtures or appliances or HVAC systems are working, the electricity arrangement will remain well maintained and harmless.

2. Business Centers: Offices, malls, etc., are business places where the electrical load on wiring is very high. Dura Conduit Pipes help to support such large-scale arrangements while securing an optimum level of protection against fires and physical hazards.

3. Industrial Applications: The wiring of industries is exposed to more aggressive chemicals, heavy machinery, and some environmental fluctuations that make the working conditions quite challenging. Dura Conduit Pipes & Fittings offers excellent electrical safety and performance under challenging conditions.

4. Subterranean and Surface Applications: For street lighting or telecom networks, the kind of electric installation carried on underground usually faces a challenge of moisture, pressure of soil, and probable weather exposition. All these applications are said to welcome Dura Conduit Pipes since these pipes were meant for such conditions.

Dura Conduit Pipes & Fittings Types

There are various types of Dura Conduit Pipes & Fittings, all intended to utilize different applications:

1. Rigigid PVC Conduits: They are used largely for residential and light commercial installations because they are non-corrosive, cheap, and light in weight, which makes them ideal general-purpose electrical conduit systems.

2. Flexible Conduits: Flexible Dura Conduit Pipes are used because they offer installation flexibility, such that they can bend around corners and obstacles without requiring additional fittings. These are particularly useful in retrofitting or renovation projects.

3. Steel Conduits: Steel conduits provide a more significant degree of protection in industrial settings because of the material’s strength and robustness. It can best be used in areas where the electrical system may, therefore, be exposed to minor damage in terms of physical aspects.

4. Fittings: Dura Conduit Fittings are made up of connectors, couplings, elbows, tees, junction boxes, and more. Each of these constitutes an essential assembly to complete a conduit system to ensure the wiring is safe and will ideally suit any structural lay design.

Environmental Factors

Today, in the eco-sensitive era, environment-friendly constructions have emerged as one of the major challenges. PVC-based Dura Conduit Pipes & Fittings are recyclable much more with lesser environmental impact compared to metallic alternatives. The extended life cycle also reduces the need for frequent replacement, thereby preventing further waste production.

More than just part of an electrical system, Dura Conduit Pipes & Fittings are a whole investment in security and efficiency with longevity.

It protects wiring from environmental hazards, the reduction of risk electrical fires, easy installation, among many more reasons that drive professionals to keep them as their trusted choice. Whether it is a small residential or a large industrial installation, the choice of Dura Conduit ensures your electrical infrastructure will last long. To an industry talking of dependability, Dura Conduit Pipes & Fittings have come through time and time again as the backbone of modern electrical systems.